Australia's Premium Supplier of 3D Printer Filaments

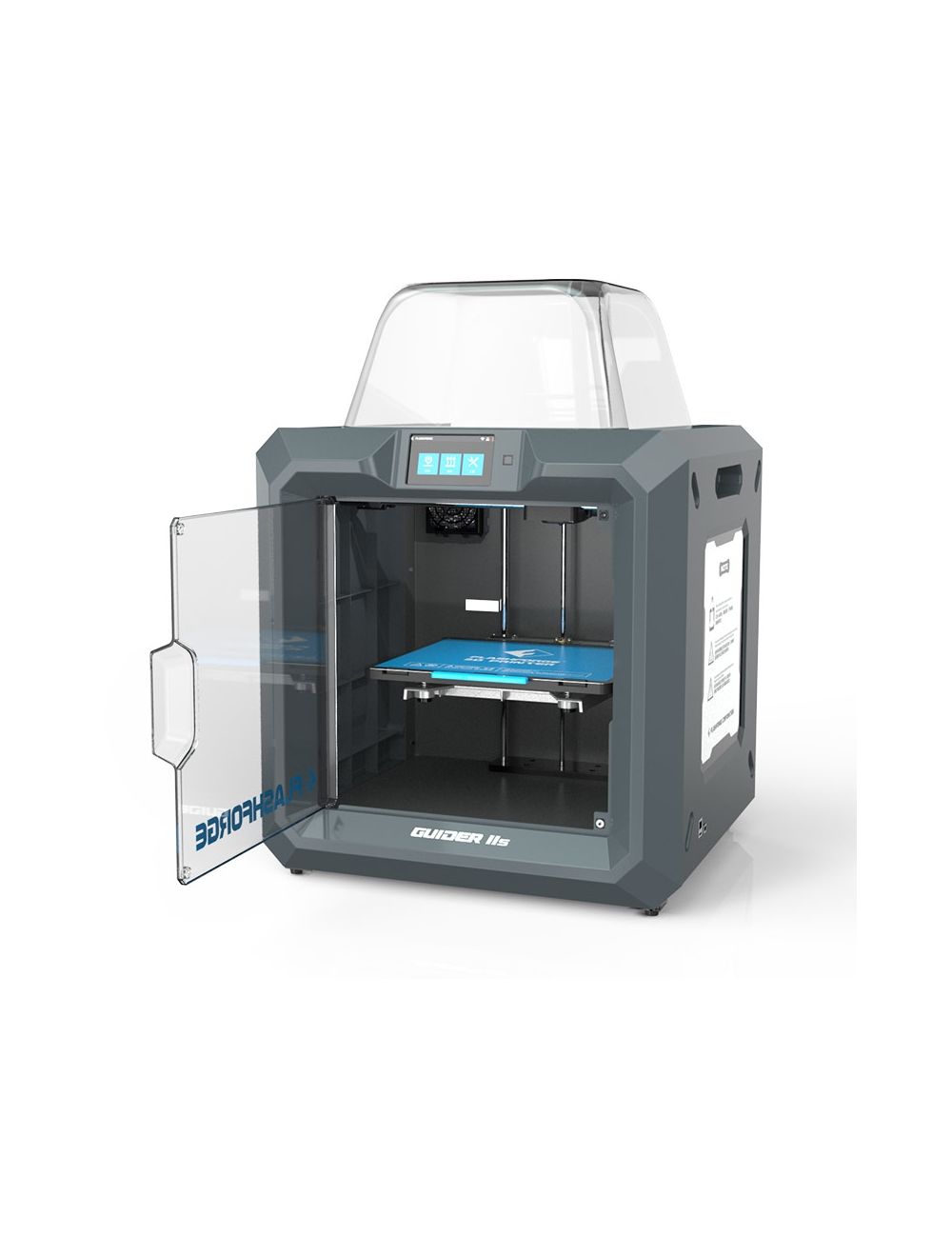

Flashforge Guider IIs V2 High Temperature Model

FREE EXPRESS SHIPPING (excluding NT). In stock now and ready to ship

Featuring; - Upgraded High-Temperature Extruder - New Flexible Build Plate - Hardened Nozzle (FREE set of various nozzles) - Fully Enclosed with Air Filtration

New Flashforge Guider IIs V2 High-Temperature Extruder

All new Flashforge Guider 2s come with a high-temperature extruder, making it ideal for printing with specialty filaments like Nylon, Carbon Fibre and HIPS.

In addition to being able to print with specialty filaments, this printer comes packed with great features like a flexible/magnetic build plate (in addition to a glass plate), filters to safely evacuate toxic fumes, and a built-in HD camera and remote monitoring

Featuring a High-Temperature Extruder

The Hotend is designed to comfortably operate within 300 degrees Celcius. Filaments such as Nylon, Carbon Fibre and HIPS require more heat than standard printers will allow. This industrial-grade printer is built with a rock-solid enclosure to allow for high temperature and even ambient temperature within the chamber during the print.

In addition to the high-temperature nozzles, we also provide you with 5 complimentary different sized nozzles for you to experiment or use. In addition to this, some tools for changing the nozzle are also provided.

When printing with PLA, the easily removable clear dome lid allows for enough heat dissipation, required for printing with rapid cooling filaments. The distinctly red part cooling shroud surrounding the nozzle is designed with multiple vents, allowing for even part cooling. Many printers come with part cooling that is single direction, which does not offer the most consistent part cooling.

Choice of Build Plates

With the Guider 2s, you have the choice of using a glass build plate or a flexible magnet build plate. Why use one over the other?

Glass build surfaces provide a very flat build surface for many materials such as PLA to adhere to. When heated the glass surface tension increases, allowing for some materials to find adequate adhesion. As the glass plate cools, the surface tension drops and allows the object to simply pop off the glass. The object also has a wonderful glass-looking sheen on the area that touches the surfaces. Further to this glass allows other adhesion materials to be used. Some people prefer to use "Blue Painters Tape" to hold the object on the plate. This tape can very easily adhere to the glass surface. A helpful tip when printing on glass is to really squish the filament onto the glass. Making sure the filament is really pressed onto the glass on the first layer will give it its best chance for adhesion.

Using a flexible magnetic build plate has other advantages. For some more "stubborn" materials that don't adhere as well to glass, the textured build plate can be very effective. The textured surface allows for more surface area for the filament to grip onto the filament compared to the flat glass. More surface area means that the first layer has a better chance for the filament to lock down the print. Sometimes for some materials putting a small amount of glue-stick can secure the object on the plate. When the plate cools down, the object can then pop off the plate quite easily. The magnetic flexible plate allows you to take the entire plate off and bend it thereby popping the object off before needing to cool it down. Please ensure you bend it within tolerances shown in the image above as the metal surface does have a yield point whereby a fold in the plate will be irreversible.

Build Volume and Enclosure

The printer has a print volume of X= 280mm, Y=250mm, and Z= 300mm.

Its solid metal enclosure is fitted with an exhaust activated carbon filter to ensure that it can capture as many fumes as possible when printing with materials such as ABS, Nylon, and ASA which produce airborne byproducts which are unhealthy for long term exposure.

The enclosure is designed to capture heat and allow consistent temperature. This is function is very important for printing materials that tend to warp during cooling. Even ambient temperatures ensure that the part does not shink in some areas which can lift corners of the part from the bed or lead to abnormal dimensional issues for the final print.

Software Connectivity

Featuring a 2-megapixel camera, you can always check your print from your computer or on your phone when you are out and about.

The Printer also connects seamlessly with your WiFi network allowing you to send files from your computer to the printer using "FlashPrint". If you also prefer, you can transfer files to your printer using the USB thumb drive provided. Furthermore, you can tether your printer to your computer with the USB cable provided.

The FlashPrint software in addition to being a print queue manager is also a powerful slicer. With a simple tabbed interface, modification of print settings couldn't be easier.

The well-designed and easy-to-use 5-inch touch screen display on the printer has been designed to intuitively navigate all the menus, from loading the filament, to even updating firmware.

Spool Holder Designed by 3DFillies

We have created a spool holder to fit our 1kg spools on this printer and it can be downloaded from Thingiverse below;

For a 1kg spool click here;

https://www.thingiverse.com/thing:4626793

For a 3kg spool click here;

https://www.thingiverse.com/thing:4662483

Printer Parameters

| Print Specifications | ||

| Extruder count | Number of extruders | 1 |

| Nozzle diameter | Optional (0.3/0.4/0.6/0.8mm) & Hardened 0.4mm Nozzle (all included) | |

| Maximum Extruder Temperature | 300c | |

| Build Volume | 280mm (L) x 250mm (W) x 300mm (H) | |

| Printer Speeds | 10-150mm/second | |

| Maximum Platform Temperature | 120c | |

| Printer Specifications | ||

| Printer Size | 550mm (L) x 490mm (W) x 570mm (H) | |

| Screen | 5 inch Touch Screen | |

| Net Weight | 30kg | |

| Power input | 240v @ 50Hz | |

| Power Usage | 500w | |

| Internal Memory Storage | 8Gb | |

| Spool Location | External | |

| Communication | ||

| Data Transfer Mediums | USB Stick, USB Cable, Wi-Fi, Ethernet, FlashCloud, PolarCloud | |

| Software (Included) | FlashPrint | |

| Output | GX/G files | |

| Input for Slicing | 3MF, STL, OBJ, FPP, BMP, PNG, JPG, JPEG |